Dental Instrument Quality Test Guidelines

Precision instruments form the heart of every dental procedure. The reliability of a probe, scaler, or mirror can directly influence patient outcomes and practitioner confidence. Regular checks and quality measures ensure every tool remains dependable, sterile, and safe. This is why following a clear dental instrument quality test framework is essential for clinics across Australia.

Why Quality Checks Matter?

Dental instruments face daily wear, repeated sterilisation cycles, and constant handling. Without regular assessment, tools can lose sharpness, develop cracks, or compromise sterility. Poor-quality equipment does more than slow down treatment; it may risk patient safety and reduce clinical efficiency.

Dental Instrument Inspection Explained

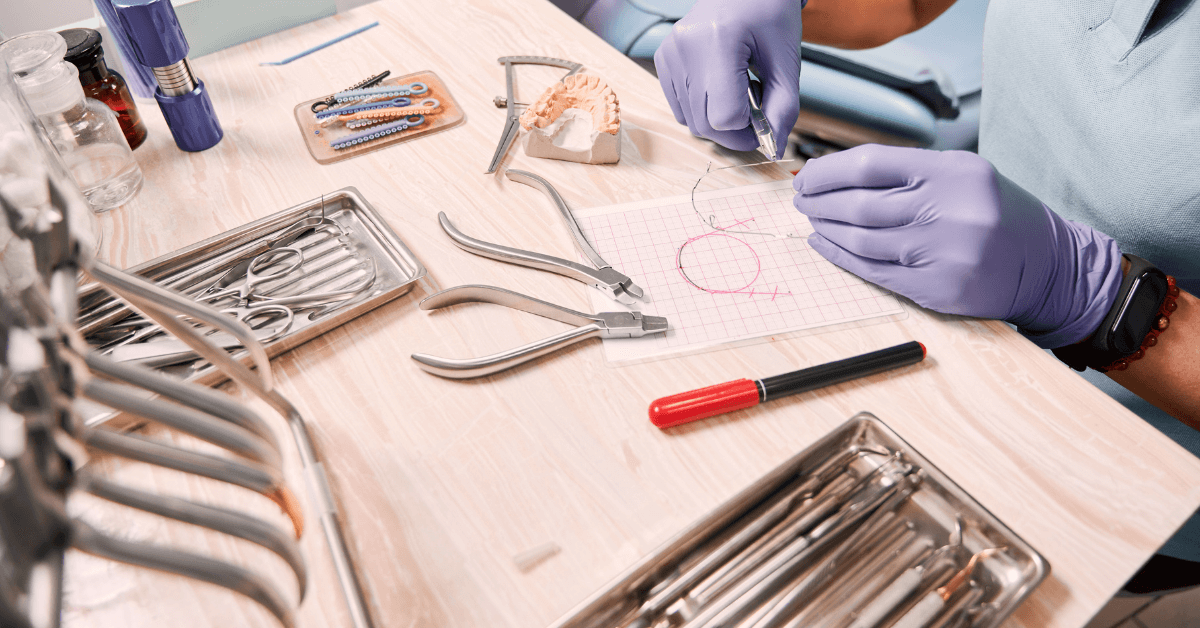

Dental instrument inspection is the process of reviewing and assessing tools for sharpness, alignment, damage, and cleanliness. This step ensures every instrument is safe and effective for patient use. A structured approach involves visual checks, tactile evaluation, and functional testing. Instruments that do not pass inspection should be repaired or replaced promptly.

A Practical Guide to Dental Instrument Care

Maintaining instruments is not just about cleaning but also about systematic evaluation. A guide to dental instrument care should include daily checks, sterilisation protocols, and scheduled servicing. By following a consistent process, dental teams avoid unexpected failures and keep patients safe throughout every appointment.

Key Areas of a Quality Test

Sharpness and Cutting Ability

Cutting instruments like scalers and curettes must remain sharp to work effectively. Dull edges force practitioners to apply more pressure, which increases patient discomfort and risks tissue trauma. Regular sharpening or replacement is a core part of maintaining tool quality.

Integrity and Structural Soundness

Cracks, loose joints, or bent tips are warning signs. Even minor flaws compromise safety and accuracy. Every inspection should focus on identifying these issues early so instruments can be serviced or safely retired from use.

Quality Control in Everyday Practice

Sterilisation and Surface Finish

Sterilised tools should maintain a smooth, corrosion-free surface. Pitting, staining, or rust indicates sterilisation concerns or compromised material quality. Instruments showing these signs should be removed from circulation immediately.

Alignment and Functionality

Forceps, pliers, and elevators must open and close smoothly. Misalignment can make procedures more difficult, prolong chair time, and cause unnecessary strain on both patient and practitioner. Smooth action is a marker of lasting quality.

Meeting Local Standards for Dental Instruments

Practices across the country are expected to comply with strict sterilisation and safety guidelines. Clinics using dental instruments should ensure their suppliers provide TGA-listed tools that meet ARTG compliance. This not only protects patients but also provides clinics with assurance during audits or inspections.

Evaluating Dental Instruments

Everyday tools such as mirrors, probes, and explorers form the backbone of dentistry. Even these basic dental instruments require consistent checks. Mirrors should remain scratch-free for clear visibility, and probes must retain precise measurements without distortion. Regular evaluation ensures they perform as reliably as more complex devices.

Training Staff in Quality Testing

A strong inspection process requires team involvement. Training dental assistants and hygienists in proper handling, cleaning, and inspection techniques ensures consistency. When every staff member understands how to identify issues, clinics maintain higher standards with less risk of oversight.

Using Checklists for Reliable Inspections

Written or digital checklists make quality testing straightforward. These lists outline what to check for sharpness, integrity, and alignment, ensuring no step is missed. Clinics that adopt checklists also benefit from easier compliance tracking during audits.

Scheduling Regular Assessments

Daily checks are important, but so are scheduled assessments. Weekly reviews allow clinics to catch issues before they escalate, while monthly or quarterly audits provide an opportunity for detailed inspections. Combining both keeps instruments safe and ready for clinical use.

Beyond The Basics: Advanced Tools

Specialised Surgical Instruments

Endodontic files, luxators, and elevators demand precise calibration. Their fine tips and slender designs make them vulnerable to wear and bending. Careful inspection ensures they remain safe for complex surgical procedures.

Digital and Modern Tools

Instruments integrated with digital systems, such as ultrasonic scalers, require both functional and electronic checks. Servicing these tools through approved providers helps maintain both accuracy and longevity.

Storage and Handling Best Practices

Safe Storage After Sterilisation

Proper storage is just as important as inspection. Instruments should be placed in sterilised pouches, trays, or cassettes to prevent damage. Cluttered storage can lead to scratches, corrosion, or misalignment.

Handling with Care

Rough handling shortens instrument lifespan. Staff should be trained to carry and place tools carefully during sterilisation and chairside use. These simple actions protect the investment clinics make in their instruments.

The Role of Suppliers in Ensuring Quality

The quality of dental tools is strongly influenced by the reliability of the supplier. Clinics that partner with trusted providers gain access to certified products, consistent stock, and professional guidance on care routines. A dependable supplier also helps clinics stay compliant with Australian standards by offering instruments that meet strict safety and performance requirements. By building a relationship with the right partner, dental teams reduce risks linked to substandard tools and ensure every procedure is supported by dependable equipment.

Balancing Costs with Long-Term Quality

Some clinics may hesitate to invest in frequent inspections or replacements. However, high-quality tools save money in the long term by reducing repair costs, preventing treatment delays, and improving patient outcomes. Investing in care today avoids costly consequences tomorrow.

Final Thoughts

When all team members commit to maintaining instrument quality, it becomes part of the clinic’s identity. Patients notice the professionalism, staff feel more confident, and the clinic strengthens its reputation as a reliable and trusted practice.

Consistent inspections, structured care, and a reliable testing process safeguard both patients and practitioners. Every clinic benefits from a clear quality framework that keeps instruments sharp, safe, and functional. By choosing high-quality dental instruments in Australia, professionals can maintain safety, efficiency, and patient trust. Dentify Dental supports this commitment by providing Australian dental professionals with dependable tools and resources that meet the highest standards of care.